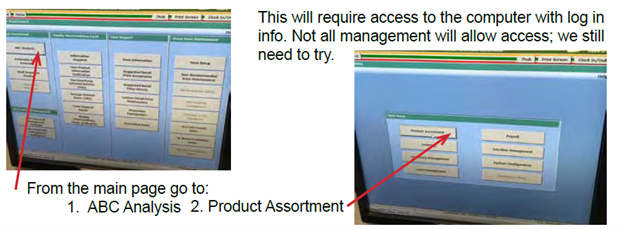

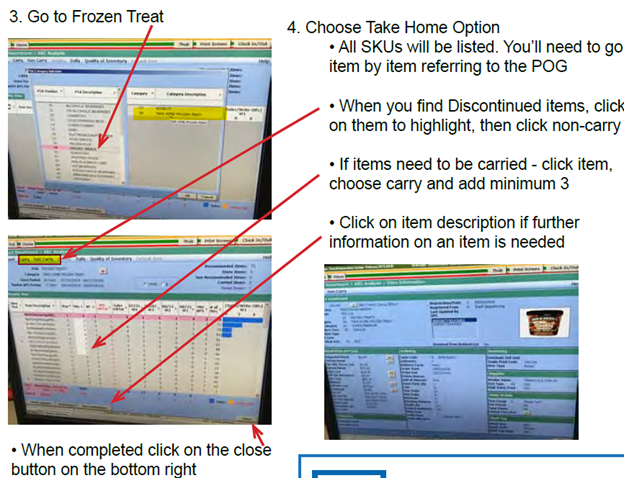

Setting Yourself up for Success at 7-ElevenSource: IAICDV Distributor Division 7-Eleven is a major customer for many of our IAICDV Distributor Members. There are constant opportunities to work with 7-Eleven stores and help 7-Eleven stores to improve their ordering. We don’t control 7-Eleven's orders anymore but there are easy tools you can use to influence, and help stores generate good quality orders and to have the right items in stock. Here are two ways: #1 Carry & Un-Carry:Unless maintained by a good operator or distributor personnel 7-Eleven stores can likely have items carried that are not good sellers or not in the planogram and can have items uncarried that they should carrying in their store. The process of reviewing and adjusting Carried and Uncarried within a 7-Eleven system can drastically improve 7-Eleven store orders and sales to 7-Eleven stores. Carry & Un-Carry: Access to store computer needed

#2 Minimums:Each sku has a minimum assigned to it. It can be overridden by the store and by you! While reviewing Carried and Uncarried a best practice is to also look at Minimums in the system by sku. This is in the same screen as above to review carried / uncarried as reviewed above. The minimum is the lowest amount of stock in inventory before the system auto-generates an order. If you see items overstocked or OOS it is likely that the minimums are not set correctly for that sku. ----------- It is worth all the effort to gain access to each 7-Eleven store back-room system and assist them in making sure that they have all planogrammed items carried, non planogrammed items uncarried and that the minimum is set accurately for the sales of the sku. We do not control the ordering at 7-Eleven stores but with good relationships and a can-do attitude we can get into their system and make adjustments to help control and improve those orders. Want to learn more? Reach out to the IAICDV Distributor Division at any time. |